World

Technology

Achieving Accuracy and Scalability Through Robotics Software and CNC Machining

New Delhi [India], October 30: Modern automation mainly relies on a robotics computer program that enhances accuracy and efficiency in any industry. Software platforms are made to be reliable with advanced assembly lines and adaptive inspection systems that reduce deviation by motion planning, correcting errors and using feedback loops.

The four cornerstones of this shift are the software-based control systems, the use of sophisticated materials such as CNC metal, rapid prototyping services enhancing speed in design cycles, and versatility in industrial application. Collectively, these aspects emphasize that robotics software is not only more accurate but also allows flexible and cost-effective production.

This article examines that automation in the modern-day competitive industry is continuously being redefined by software.

Software Driven Control and Precision

The ultimate principle of robotics is the repetitive action of complex movements with a regular precision. Advances in software on some technologies like the kinematic modelling, adaptive path corrections and sensor fusion will also assure a robot that it will not lose track even when faced with certain scenarios of uncertainties. The feedback is real time and as such can make adjustments in the number of milliseconds that enable it to minimize the errors when executing a task in welding, cutting or assembling.

The degree of accuracy is not mechanical, but algorithmic. Machine learning models optimize movements such as tool wear trends, vibration, material variation. Greater amounts of adaptive intelligence are primarily relevant to very demanding sectors such as semiconductor manufacture and medical devices manufacture where acceptance limits are generally being of the order of microns.

It also goes hand in hand with modular programming where an engineer can redesign robotic processes dynamically without linking the processes to the rest of the system. With physical material like CNC metal structures, robotics achieves a fallacy in which digital accuracy and material consistency drives results.

The Role of Materials and CNC Metal

The accuracy of robotics does not rely just on the algorithms themselves, but also on materials of machines structure. The robots undergo numerous stress cycles on their robotic arm, robot joints, and robot base components made using CNC metal machining to ensure they are aligned. Tolerance machining enhances backlash (a minimization of deformation), rigidity (consistent performance), and rigidity.

Robotic hardware uses aluminum, titanium and stainless steels, but it is machining these alloys that characterizes their value. In CNC metal operations, the tolerances achieved by the manufacturers are on the level of microns, which sustains the software-defined motions on a steady mechanical platform. This merging of both material engineering and robotics software allows systems to take on complicated tasks such as assembling aerospace, high-speed packaging, and rely on them 100 %.

Moreover, machined housings and brackets enable activity of a seamless integration of sensors, actuators, and wiring. The feedback systems that are software controlled require the correct placement of these which is vital and digital control cannot be done without material accuracy.

Rapid Prototyping Services and Agile Development

Technological agility in robotics innovation requires an equally fast rate of development. In this, rapid prototyping services help to overcome this requirement as they seal the gap between a computer model and a functional part. The tools facilitate engineers to develop tests of the designs in a short period of time, to examine and evaluate the ergonomics of the design, and additionally to alter mechanical mapping designs prior to huge manufacturing batches. This quality accelerates the process of decision making and reduces the design flaws which are highly costly.

Robotics software has digital simulations on which physical prototypes are run to complementary knowledge on a team. Software predicts movement efficiency, energy utilization and path precision, such prototypes make aspects such as load handling or life cycle real-world. Examples As an example, end-effector or gripping mechanism tests (Both physical and computer-based) are beneficial. The rapid prototyping services have made this kind of cycle possible in a matter of days, rather than months, making the process of developing these types of cycles significantly shorter.

In the CNC metal machining, the process remains improved with the production of prototypes that are capable of simulating the performance of the industry. The shapes and ergonomics are proven in plastic models, and stress is paid on metal prototypes. These two methods together ensure the stability of robots in simulations and rough field conditions.

Scalable Industrial Adoption

Scalable industrial applications have enjoyed its most significant influences where robotics software has proven to yield incredible power, much bigger than when applied in the context of research. Such systems can be installed in automotive, electronic, logistics, and healthcare industries to boost growth and flexibility. The possibility to model entire production lines has allowed digital twins to predict bottlenecks and producers can validate reconfigurations and layout optimization before they are applied. This predictive capability reduces downtime and provides maximum throughput, thus adding resilience to large-scale activities.

The aspect of regularity is also important in implementation of robotics in thousands of units. CNC metal machining is a plan that ensures that the parts are produced to identical requirements in order to ensure that robot platforms can be both interchangeable and uniform. Software operates on the principle where each unit is calibrated to normalize the performance and ensure that performance in large fleets is a correct one. The accuracy of hardware, in conjunction with customizable software, gives a foundation of versatile automation.

Rapid prototyping services added to these processes and contributes to the flexible scaling process. Gripper, housings, or mounts can be mounted and examined as new variants without affecting current production. This host-software-prototyping synergy is allowing industries to evolve hastily, with different requirements being addressed without duties being pulled on the quality and accuracy.

Conclusion

The accuracy of modern industries has been revamped by robotics software. Rapid prototyping services alongside adaptive control of their behavior have allowed robots to reach previously unrealistic material accuracy through integration with CNC metal, enabling fast turnover of hardware projects, and rapid material prototyping. Scaling to software intelligence and precision in manufacture brings assurance of application to all industries. Robotics software will continue to lead future innovation as industries require greater precision and reduced time to deliver services.

If you have any objection to this press release content, kindly contact pr.error.rectification@gmail.com to notify us. We will respond and rectify the situation in the next 24 hours.

National

Team Korea and Good Neighbors Lead Menstrual Hygiene Awareness Initiative in Jaipur

Promoting Health, Education, and Dignity for Adolescent Girls in Rajasthan

Jaipur (Rajasthan) [India], November 3: As part of the Team Korea CSR Initiative, the Embassy of the Republic of Korea in India, the KOTRA India–Korea Business Cooperation Centre, and Good Neighbors jointly organised the “Menstrual Hygiene Awareness and Dignity Initiative” at Government Girls Senior Secondary School (GGSSS), Chaksu, Jaipur.

During the program, menstrual hygiene kits were distributed to 285 adolescent girls, each containing 3-month supply of sanitary napkins, underwear, hand sanitiser, hand towel, pouch, hot water bag, and an informative brochure. Experts also conducted awareness sessions on menstrual health and hygiene management to promote better understanding and healthy practices.

The event was graced by Ms. Punita Sharma, Chief Block Education Officer, and Mr. Mahesh Sharma, Assistant Chief Block Education Officer, Chaksu Block Education Office; Ms. Lavina Rathore, State Lead, Educate Girls Globally, Directorate of Women Empowerment, Jaipur as a resource person; and Dr. Sanjay Kumar Meena, Principal Medical Officer and Gynaecologist, who led an insightful session on menstrual hygiene and adolescent health. The school principal delivered opening remarks, emphasising the importance of menstrual health awareness in promoting well-being and confidence among young students.

“We believe that empowering adolescent girls with knowledge about menstrual hygiene is fundamental to ensuring their health, dignity, and education,” said a representative from the Embassy of the Republic of Korea in India. “Through this initiative, we hope to create awareness and help young girls feel confident and supported.”

Representatives from the Embassy of the Republic of Korea in India, KOTRA India–Korea Business Cooperation Centre, Good Neighbors, and school officials attended the event, reaffirming their shared commitment to supporting adolescent girls’ health and empowerment through education and awareness and reducing absenteeism.

If you have any objection to this press release content, kindly contact pr.error.rectification@gmail.com to notify us. We will respond and rectify the situation in the next 24 hours.

Education

Latest News

Dosti Realty Partners with Primus to launch MMR’s Landmark Senior Living Community

Mumbai (Maharashtra) , November 3: Dosti Realty, one of the most trusted names in the Mumbai Metropolitan Region (MMR), has partnered with Primus, India’s leading senior living brand, to introduce…

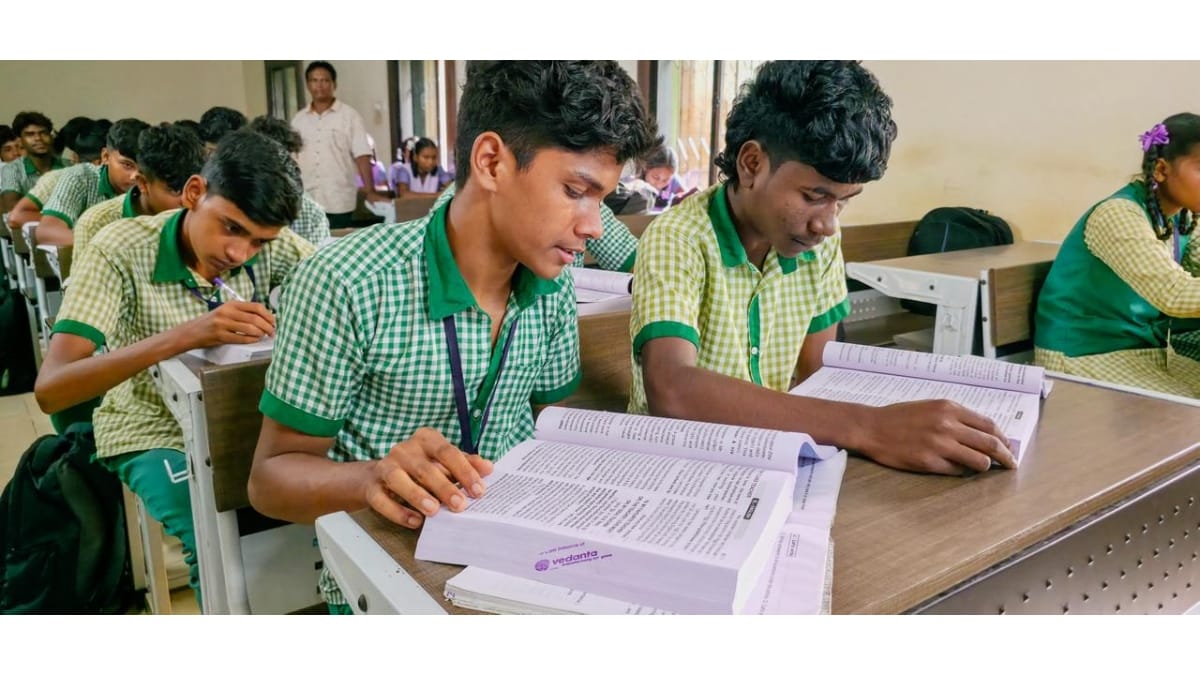

Vedanta Aluminium Empowers 600 Students with Academic Resources under Project Vidya

Bhubaneswar (Odisha) , November 3: Vedanta Aluminium, India’s largest producer of aluminium, has reaffirmed its commitment to quality education in rural Odisha through its flagship initiative, Project Vidya. As a…

CID’s Iconic Duo Dayanand & Aditya Reunite in a Fresh Avatar for Suspense Thriller ‘Hello Knock Knock Kaun Hai’

New Delhi , November 3: For over two decades, Dayanand Shetty and Aditya Srivastava have been beloved household names, known to millions as the formidable duo “Daya and Abhijeet” from…

Echosens Opens Regional Headquarters in India, Strengthens Commitment to Liver Health Across South Asia

Mumbai (Maharashtra) , November 3: Echosens, the leader in non-invasive liver diagnostics, today announced the opening of its new regional headquarters* in Mumbai, India. The new office in the Bandra…

GHV Infra Projects Reports 128% Surge in Revenue and 138% Jump in Profit, Driving Strong Growth Momentum in Q2 F Y2025–26

Mumbai (Maharashtra) , November 3: GHV Infra Projects Limited (‘the Company’) (BSE – 505504), engaged in EPC/turnkey project execution across Infrastructure (road, rail, water, airport runways, ports, and energy), Industrial…